The Challenge:

A leading valve manufacturer sought to develop a new product variant that combined features of two existing models, requiring R&D support, API 641 compliance, competitive production costs, and rapid scale-up from prototype to mass production.

Our Approach:

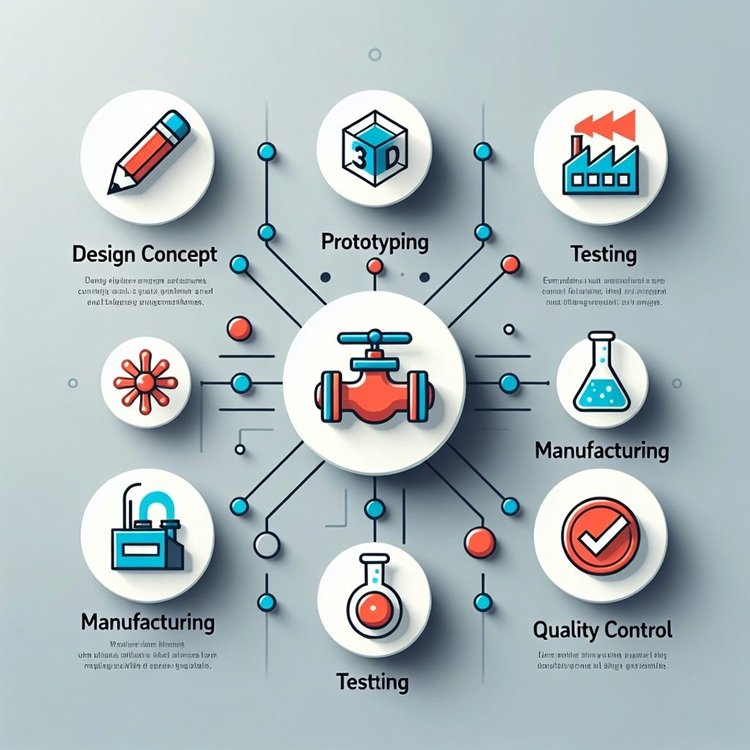

TES Global partnered closely with the client’s engineering and sourcing teams to guide the product from concept to launch:

- Design Refinement: Improved Manufacturability, Durability, and Cost Efficiency.

- Vetted Manufacturing Partner: Audited Technical Capabilities, Compliance Systems, and Production Capacity.

- Rapid Prototyping: CAD models, 3D-printed Prototypes, Functional Samples, and Iterative Testing.

- Certification Support: Secured API 641 and Fire-Safe Approvals.

- Scale-Up & Logistics: Delivered 10,000 units in year one with end-to-end quality and timely delivery.

The Results:

- Time-to-Market reduced from 18 months to 12 months.

- 30% cost savings over U.S.-based prototyping estimates.

- Full compliance with API and fire-safe standards.

- Successful mass production, meeting all launch deadlines.

Client Testimonial:

“TES Global guided us with complete ownership in the design, manufacturing, and logistics of one of our most challenging products. We not only launched on time and at scale because of them, but the product is one of our most successful products to-date.”

At a Glance:

From concept to certified, market-ready product, TES Global delivered the engineering insight, manufacturing expertise, and global coordination needed to bring a new valve variant successfully to market.

Contact Us

Get in touch with TES Global to discuss your projects, solutions, or partnership opportunities.